| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Rod End Connector |

|---|---|

| Brand Name: | PHIDIX |

| Model Number: | Customized |

| Certification: | IATF16949 |

| Place of Origin: | China |

| MOQ: | 100 Piece/Pieces |

| Price: | Negotiation |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Supply Ability: | 888 Piece/Pieces per Month |

| Delivery Time: | 7-40 work days |

| Packaging Details: | carton or wood case |

| Name: | Aluminum Pillow Block Bearing Arms |

| Brand: | Phidix |

| Certificate: | IATF16949 |

| Material: | Aluminum |

| Overall Length: | Customizable |

| Operating Temperature: | −20°C To +120°C (Bearing Dependent) |

| Surface Treatment: | Anodized, Clear Coat,Or Hard-Coat Options |

| Bearing Type: | Sealed Ball Bearing Or Roller Bearing (Custom Options Available) |

| Load Capacity: | Medium To High Load Ratings Depending On Size |

| Customization: | Machining Of Arm Length, Hole Spacing, And Bearing Type Available |

| Company Info. |

| Phidix Motion Controls (Shanghai) Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

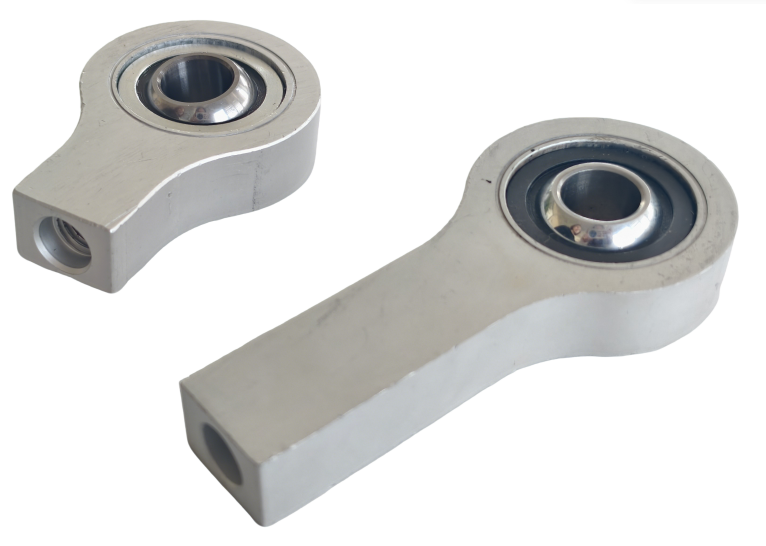

Aluminum Pillow Block Bearing Arms

【 Product Description 】

These aluminum pillow block bearing arms are heavy-duty mechanical components designed to connect rotating shafts with linear or articulated systems. Available in short and long configurations, each arm integrates a sealed ball bearing (for smooth rotation) and a threaded mounting hole (for secure installation). Machined from high-strength aluminum alloy, they balance lightweight design with impact resistance—ideal for industrial machinery, vehicles, and custom mechanical projects requiring reliable, low-friction linkage.

【 Application 】

•Industrial machinery

•Vehicles

•Robotics and manipulators

•Conveyor systems

•Agricultural machinery

•Light-industrial machinery

【 Features 】

•Lightweight Aluminum Construction – Reduces system weight for improved dynamic performance.

•Corrosion-Resistant Surface – Anodized finish enhances durability in humid or corrosive environments.

•Precision Bearing Housing – Ensures stable support of rotating shafts with minimal vibration.

•Integrated Mounting Arms – Allows quick installation and easy alignment.

•Multiple Configurations – Available in various bearing types and shaft sizes.

•Low Maintenance – Sealed bearings require minimal lubrication.

【 Advantages 】

•High Strength-to-Weight Ratio: Aluminum alloy provides excellent mechanical performance while keeping weight low.

•Improved Operating Efficiency: Reduced system inertia supports higher operating speeds.

•Versatile Integration: Suitable for a wide range of mechanical assemblies and custom projects.

•Enhanced Stability: Precision-machined housing keeps the shaft supported and aligned under load.

•Cost-Effective Manufacturing: Aluminum machining enables flexible customization at lower cost compared to steel.

•Long Service Life: Corrosion protection and sealed bearings extend operational lifespan.

【 Real Picture 】

|