| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | PP Strap Extrusion Machine |

|---|---|

| Brand Name: | HL |

| Model Number: | HL-PP |

| Certification: | CE SGS |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 set/Monthly |

| Delivery Time: | 20-30days |

| Packaging Details: | PE film |

| Name: | PP packaging belt equipment |

| Width: | 5-19 mm |

| Thickness: | 0.3-1.2 mm |

| Motor power: | 55KW |

| Production capacity: | 110-600 kg/ h |

| Control Mode: | PLC |

| Material: | PP |

| Environmental protection: | YES |

| automatic winding machine: | YES |

| Plastic extruder: | PP |

| Screen changer: | automatic screen changer |

| Metering pump: | 50 CC |

| Company Info. |

| Hainan Huili Packaging Products Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

PP belt making machine 5-19mm PP strapping production line high-speed PP/PET extrusion equipment

PRODUCT DESCRIPTION OF PP STRAP MAKING MACHINE:

PP Strap Making Machine

PP strapping machine/PP packing strap equipment can use 100% recycled materials or virgin PP polypropylene materials to produce packing straps;

Width: 5-19mm;

Thickness: 0.3-1.2mm

Main Components:

Extruder------ Heats and melts PP raw material (polypropylene pellets or recycled material) and extrudes it into a shape through a screw.

Extrusion Die------ Molten PP passes through a die to form a strip, which determines the width and thickness of the strapping tape.

Cooling Water Tank: Rapidly cools and shapes the hot strip, ensuring its strength and surface smoothness.

Stretching System------- Longitudinally stretches the strip using multiple sets of heated and pulling rollers (a hot stretching process), increasing its tensile strength and toughness.

Embossing Device--------- Imprints patterns or logos on the strip surface, increasing friction and aesthetics.

Reel: Winds the finished strapping tape into a roll, typically equipped with automatic roll-changing and cutting functions.

Raw materials-------

100% virgin or recycled PP polypropylene

EXTRUSION PARAMETERS TABEL

| Model | PP-2 | PP-4 | PP-6 | PP-8 | PP-10 | PP-12 |

| Raw material | PP polypropylene new material/recycled material | |||||

| Number of tapes | 2 | 4 | 6 | 8 | 10 | 12 |

| Width(mm) | 5-19 | 5-19 | 5-19 | 5-19 | 5-19 | 5-19 |

| Thickness(mm) | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 | 0.4-1.2 |

| Line speed(m/min) | ≧260-300 | |||||

| PLC control system | PLC | PLC | PLC | PLC | PLC | PLC |

| Screw Model | 90 | 110 | 125 | 135 | 135 | 135 |

| Reducer model | 200 | 220 | 250 | 280 | 280 | 280 |

| Drying barrel (kg) | 100 | 150 | 200 | 200 | 200 | 200 |

| Winding machine | Automatic winding machine /Semi-automatic winding machine | |||||

| Screen Changer | Automatic/Manua | |||||

| Production capacity 24H | 2.5-3T | 6-7T | 8-9T | 10-11T | 12-13T | 13--14T |

What are the advantages of PP Strap Making Machine?

## High-Efficiency Production Expert

PP strapping equipment/PP Strap Making Machine is a highly efficient, fast, and high-capacity extrusion machine. It can continuously produce high-quality PP strapping with amazing efficiency. The line speed is 100-300 m/minute. Compared with traditional production methods, it can complete the production of a large number of straps in a shorter time, greatly improving overall production efficiency. With it, even with many orders, you won't be afraid!

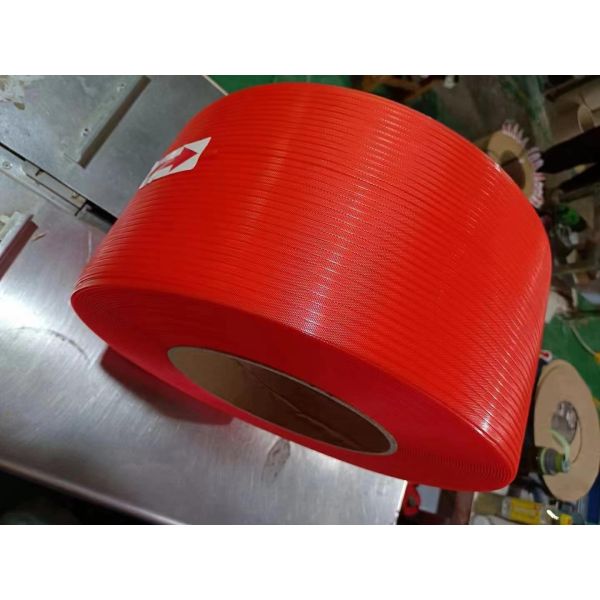

Finished PP packing straps:

PP strapping belt is suitable for baling machines:

Fully automatic strapping machine

Semi-automatic strapping machine

High-speed ultra-thin strapping machine

Handheld electric strapping machine

Manual strapping machine (iron buckle)

About th SERVICE:

We provide comprehensive technical support and service for our PP Strap Making Machine. Our team of experienced technicians can provide a variety of services, including:

Pre-sales:

1.Layout plan of PP belt making machine.

2.Analysis of the cost of PP belt making machine.

3.Raw materials that can be used for PP belt making machine.

After-sales service:

1.Water and electricity circuits of PP belt making machine, circuit drawings, etc.

2.Installation, commissioning and training of PP belt making machine.

3.Maintenance service of PP belt making machine.

4.Regular maintenance and repair

5.Troubleshooting and diagnosis

6.Software updates and upgrades

7.Spare parts and accessories

8.Training and technical advice

FAQ:

Q:What is the voltage of PP belt making machine?

A:380V/50HZ, we support customization

Q:What is the length of the PP strapping belt?

A: L:36 M.

Q:Where is the PP belt making machine produced?

A:We are from China.

Q:Can PP belt making machine provide after-sales service?

A:Yes, we have professional after-sales engineers who provide

24-hour online guidance.

Q:Is the quality of PP belt making machine stable?

A:We have 30 years of manufacturing experience, and have their own

PP packaging belt production plant, equipment quality is stable,

the process is worth choosing.

Q:Does PP belt making machine support customization?

A:We are a manufacturing plant that can customize model size,

extrusion capacity, voltage and so on according to customer

requirements.

Q:What does the wrapping machine part of the PP belt making machine look like?

A:Equipped with automatic wrapping machine/semi-automatic wrapping machine.

|