| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Sanitary Napkin Making Machine |

|---|---|

| Brand Name: | Womeng |

| Model Number: | WM-NVS02 |

| Certification: | CE,ISO9001,SGS |

| Place of Origin: | Fujian, China |

| MOQ: | 1 piece |

| Price: | $300,000-$400,000 |

| Payment Terms: | L/C,D/A,D/P,T/T |

| Supply Ability: | 12sets/year |

| Delivery Time: | 60-100days |

| Packaging Details: | Seaworthy Wooden Box |

| Design: | Full Servo Control System |

| Warranty: | 1 year |

| Production Process: | Automatic |

| Shipping Port: | Xiamen port |

| After-sale Service: | Engineers available to service machinery overseas,Video technical support,Field maintenance and repair service,Field installation |

| Hs Code: | 84418090 |

| Machinery Test Report: | Provided |

| Regional Customization: | Support |

| Company Info. |

| Quanzhou Womeng Intelligent Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

| Attribute | Value |

|---|---|

| Production Speed | 800-1200 pieces per minute |

| Product Size | 240mm,290mm,320mm,420mm(Customized according to customer requirement) |

| Production Yield Rate | ≥98% |

| Weight | About 50 tons |

| Machine Size | 25x4x3m |

| Safety System | It has safety device on the operating side, matched with urgent stop switch.High audio fan uses sound insulation or silencer. |

| Raw Material | Fluff pulp, SAP, non-woven fabric, PE film |

| Control System | PLC control system(Mitsubishi),HMI Operating on the LED touch |

| Drive system | Servo Drive(Easy to change size), timing belt and flat belt are import products, and all the key parts, are import bearings. |

| Power | 240V,50Hz,3 Phase Five Wire |

Technical features:

* Compact design, easy operation & maintenance

* Modular design, for future upgrading

* Low consumption, high efficiency

* Servo or frequency inverter transmission

* Touch screen for man-machine conversation

* Auto record and calculation of process data

* Main raw material auto splicing at zero speed

* Inverter or servo unwinding with tension control

* Web guiding controller

* Sensor quality control systems

* Material broken and lost inspection, auto machine stops and

defective products auto rejection

* Easy size changing and manufacture

| Core Structure | Sub-Structure | Main Materials | Key Features |

| Surface Layer | Skin-Friendly Layer | Combed Cotton,Bamboo Fiber | Soft, skin-friendly, breathable |

| Breathable Layer | Microporous Non-Woven Fabric | Moisture-wicking, reduces stuffiness | |

| Distribution Layer | Rapid Penetration Layer | High-Puff Non-Woven Fabric | Fast liquid absorption, no local accumulation |

| Despersion Layer | Patterned Non-Woven Fabric | Even liquid distribution | |

| Absorbent Core | SAP Locking Layer | Super Absorbent Polymer (SAP) | High water absorption, anti-reverse osmosis |

| Support Layer | Fluff Pulp, Hollow Fiber | High water absorption, anti-reverse osmosis | |

| Leak-Proof Bottom | PE Breathable Film | Polyethylene Breathable Film | Waterproof, breathable |

| Anti-Slip Adhesive | Medical-Grade Adhesive | Secure fit, no displacement | |

| Wings | Fixing Wings | Rigid Non-Woven Fabric | Anti-side shift |

| Leak-Proof Edges | Elastic Non-Woven Fabric | Enhanced side leakage protection |

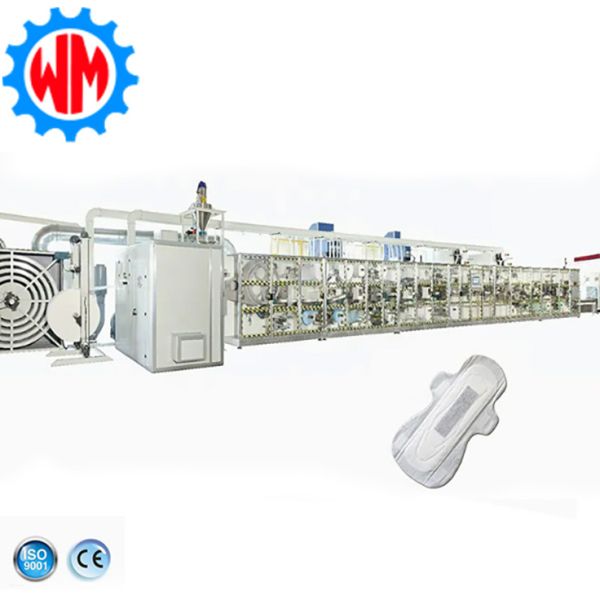

Machine Panoramic Image

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Whatsapp: +008615805080212

https://www.diapersmachines.com

Reduce reliance on energy and consumables, and adapt to regions with limited resources

Low energy consumption adapted to high energy cost markets:

In addition to intelligent power regulation, the production line can switch to an "energy-saving mode", further reducing energy consumption by 10% to 15% while ensuring product quality. For regions with tight power supply or high electricity bills (such as some countries in Africa), "off-peak production" suggestions can be combined to help buyers reduce energy expenses and lower operating costs.

General consumables are easy to purchase and there is no risk of supply disruption:

The lubricants, cleaners, hot melt adhesives and other consumables needed for production are all international common models. There is no need to rely on the original factory for supply. Buyers can easily purchase them in the local industrial market, with affordable prices and stable supply. At the same time, we provide optimization solutions for consumable usage, such as precisely controlling the amount of hot melt adhesive sprayed to reduce consumable waste and further lower costs.

Strengthen the adaptability to the production environment and deal with extreme working conditions

Wide temperature and humidity adaptability, not afraid of climate differences:

The equipment can operate stably within a temperature range of -10 ℃ to 45℃ and a humidity range of 30% to 90%. It can not only adapt to the hot and dry climate of the Middle East and the high-humidity and muggy climate of Southeast Asia, but also handle the low-temperature environment of high-latitude regions. There is no need to configure additional constant temperature and humidity equipment, reducing the cost of factory renovation.

Voltage fluctuation adaptive, no need for voltage stabilizer:

In addition to supporting a wide voltage input range of 180V-240V, it also features a voltage fluctuation adaptive function. When the voltage fluctuates by ±20% instantaneously, the device can automatically adjust the power output to prevent shutdown or product scrapping. It is particularly suitable for regions with unstable power supply such as Africa and South Asia, ensuring the continuity of production.

|