| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Heat Resistant Steel Castings |

|---|---|

| Material: | Cast Iron |

| Size: | As Per Customer's Drawings |

| Service: | OEM |

| Cast Process: | Sand Cast Process |

| Surface Treatment: | Shot Blast |

| Wearresistance: | Excellent |

| Application: | Machinery Parts |

| Corrosionresistance: | High |

| Company Info. |

| Eternal Bliss Alloy Casting & Forging Co.,LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

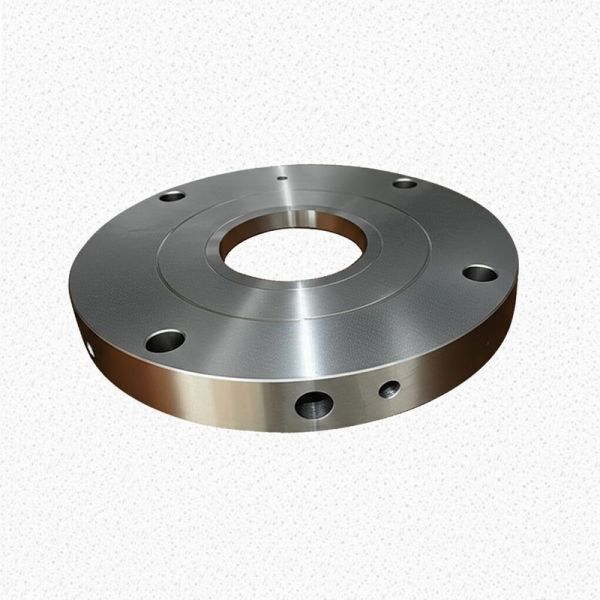

Heat Resistant Steel Castings are specialized components manufactured primarily from cast iron, designed to withstand high-temperature environments while maintaining structural integrity and performance. These castings are produced through a meticulous casting process, specifically utilizing the sand cast process, which allows for the creation of complex shapes and sizes tailored to meet the demanding requirements of various industrial applications. The use of cast iron as the base material ensures a robust foundation, providing excellent durability and resistance to thermal stress.

The manufacturing process begins with the sand cast process, a widely recognized method in the metal casting industry. This process involves creating a mold from a sand mixture, into which molten cast iron is poured. As the molten metal cools and solidifies, it takes the shape of the mold, forming the desired casting. This method is highly effective for producing Heat Resistant Alloy Castings because it allows for precision, cost-efficiency, and flexibility in design, making it suitable for both small and large production runs.

One of the key attributes of these Heat Resistant Steel Castings is their low to moderate thermal conductivity. This characteristic is crucial for applications where heat retention or insulation is necessary. The low thermal conductivity of cast iron helps in minimizing heat loss, thereby enhancing energy efficiency and protecting adjacent components from thermal damage. This makes Heat Resistant Alloy Castings ideal for use in furnaces, boilers, heat exchangers, and other equipment exposed to elevated temperatures.

To further enhance the mechanical properties and heat resistance, the castings undergo specialized heat treatment processes such as annealing, normalizing, or quenching and tempering. Annealing involves heating the casting to a specific temperature and then cooling it slowly to relieve internal stresses and improve ductility. Normalizing, on the other hand, is a heat treatment process that refines the grain structure and enhances toughness by heating the casting above its critical temperature followed by air cooling. Quenching and tempering combine rapid cooling with reheating to achieve a balance of hardness, strength, and toughness. These treatments ensure that Heat Resistant Alloy Castings can endure thermal cycling and mechanical loads without deformation or failure.

The versatility of Heat Resistant Steel Castings makes them indispensable in various industries, including power generation, petrochemical, automotive, and manufacturing. Their ability to perform reliably under extreme heat conditions, combined with the strength and wear resistance of cast iron, allows engineers and designers to develop equipment that meets stringent safety and performance standards. Moreover, the sand cast process provides the adaptability needed to customize castings for specific applications, ensuring optimal fit and function.

In summary, Heat Resistant Steel Castings produced from cast iron through the sand cast process represent a crucial solution for high-temperature industrial challenges. Their low to moderate thermal conductivity, coupled with advanced heat treatment techniques such as annealing, normalizing, and quenching and tempering, results in components that offer exceptional durability, thermal stability, and mechanical strength. These attributes make Heat Resistant Alloy Castings a preferred choice for industries requiring reliable performance in harsh thermal environments. By leveraging the benefits of cast iron and precise manufacturing methods, these castings continue to play a vital role in enhancing operational efficiency and longevity of thermal equipment worldwide.

| Application | Machinery Parts |

| Size Range | Custom Sizes Available Depending On Casting Capabilities |

| Furnace Type | Gas Furnaces |

| Wear Resistance | Excellent |

| Size Tolerance | CT10 |

| Service | OEM |

| Heat Treatment | Annealing, Normalizing, Or Quenching And Tempering |

| Material | Cast Iron |

| Feature | Quenching |

| Cast Process | Sand Cast Process |

Heat Resistant Steel Castings produced through the sand cast process are essential components in a variety of industrial applications where durability and resistance to extreme temperatures are critical. These Heat Resistant Alloy Castings are specifically designed to withstand high thermal stress, making them ideal for use in environments exposed to intense heat and corrosive conditions.

One of the primary application occasions for these Heat Resistant Alloy Castings is in the manufacturing of machinery parts. Industries such as power generation, petrochemical, and metal processing rely heavily on components that can endure prolonged exposure to high temperatures without compromising structural integrity. The sand cast process ensures that each casting has excellent dimensional accuracy and mechanical strength, which is crucial for parts subjected to continuous thermal cycling.

The versatility of Heat Resistant Steel Castings extends to their surface treatment options as well. Shot blast treatment enhances the surface finish, improving the castings’ resistance to wear and corrosion. This makes them suitable for use in gas furnaces, where components must resist oxidation and thermal fatigue. Gas furnaces, known for their high-temperature operations, benefit greatly from the superior heat resistance and longevity provided by these alloy castings.

Additionally, the service of OEM customization allows manufacturers to procure Heat Resistant Alloy Castings tailored to specific machinery requirements. Whether it is intricate design specifications or particular material compositions, OEM services ensure that the castings meet the exact needs of the end application, enhancing performance and reliability in demanding industrial scenarios.

In summary, Heat Resistant Steel Castings made via the sand cast process and treated with shot blast surface finishing are indispensable in high-temperature machinery parts applications. Their ability to withstand harsh thermal environments, combined with OEM customization and compatibility with gas furnace operations, makes these Heat Resistant Alloy Castings a preferred choice for industries seeking durable and efficient heat-resistant components.

Our Heat Resistant Steel Castings are engineered to withstand extreme temperatures and harsh operating conditions, ensuring durability and long service life in demanding applications. We offer comprehensive technical support to assist you with material selection, design considerations, and performance optimization tailored to your specific needs.

Our services include expert consultation on heat treatment processes, machining, and installation guidelines to maximize the efficiency and reliability of the castings. We also provide detailed documentation and testing reports to guarantee product quality and compliance with industry standards.

For any technical inquiries or service requests related to Heat Resistant Steel Castings, our dedicated support team is ready to provide prompt and professional assistance to help you achieve optimal results in your projects.

|