①HIWIN WEW50CC Linear Guideway Blocks 50mm Hiwin Machine Tool

Guideways

The HIWIN WEW50CC Linear Guideway Block represents a premium motion solution engineered for heavy-duty

machine tool applications where precision, rigidity, and long-term

reliability. Designed with a 50mm width profile, this robust

guideway system delivers exceptional load capacity and vibration

damping, making it ideal for high-performance CNC machining

centers, milling equipment, and large-scale industrial automation

systems. Its hardened and precision-ground raceways ensure smooth,

near-frictionless motion while maintaining micron-level accuracy

even under extreme cutting forces or multidirectional loads. The

WEW50CC's advanced sealing technology effectively shields critical

components from coolant ingress, metal chips, and abrasive

contaminants—extending service life in harsh machining

environments. Optimized preload settings provide enhanced stiffness

for demanding operations like heavy milling or deep-hole drilling,

where tool deflection must be minimized to maintain surface finish

quality. The guideway's modular design allows for easy integration

into both new and retrofitted machine tools, reducing downtime

during installation or maintenance. With its ability to sustain

high feed rates without compromising positional accuracy, this

linear motion solution helps manufacturers achieve tighter

tolerances, improved repeatability, and higher metal removal rates.

Whether deployed in aerospace component production, automotive die

manufacturing, or precision mold making, the HIWIN WEW50CC delivers

the uncompromising performance required by modern machine tools

operating at the forefront of industrial productivity. Its

combination of rugged construction and precision engineering makes

it a trusted choice for equipment manufacturers seeking to push the

boundaries of machining capability while ensuring years of

trouble-free operation.

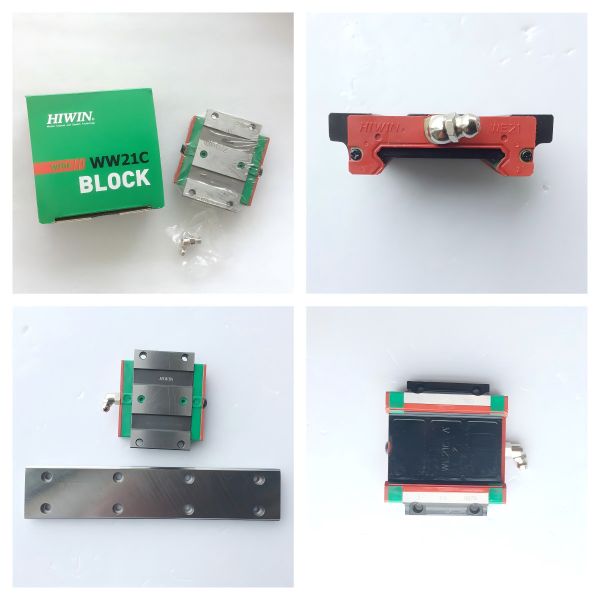

②Drawing of WEW50CC

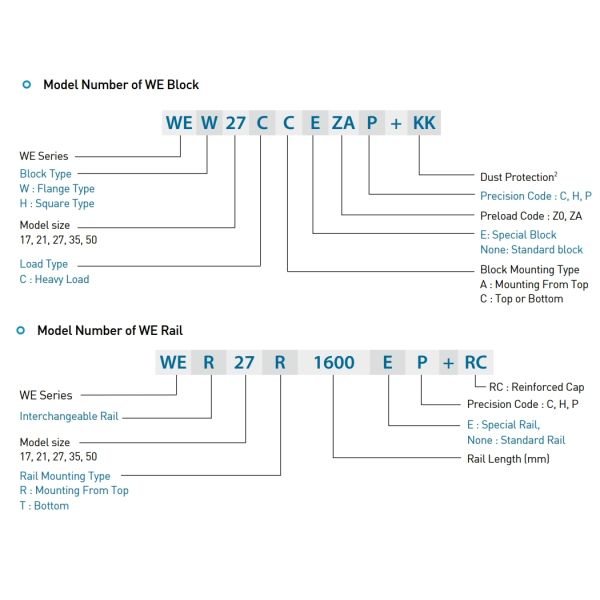

③Model Number of WE Series

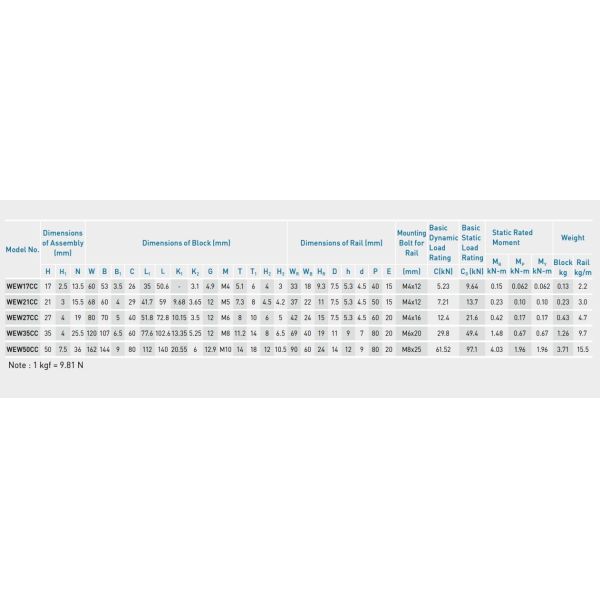

④Construction of WE Series

1.Rolling circulation system: Block, rail, end cap and retainer

2.Lubrication system: Grease nipple and piping joint

3.Dust protection system: End seal, bottom seal, cap and scraper.