| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Ball Screw |

|---|---|

| Brand Name: | TBI |

| Model Number: | BSHR0082.5 |

| Certification: | DE1924083895474 |

| Place of Origin: | CHINA TAIWAN |

| MOQ: | 1 |

| Price: | 1-100 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,Western Union |

| Supply Ability: | 100000 pcs / per month |

| Delivery Time: | 1-7 work days |

| Packaging Details: | Small or with carton box, Bulk order with Wooden box |

| Series: | BSHR |

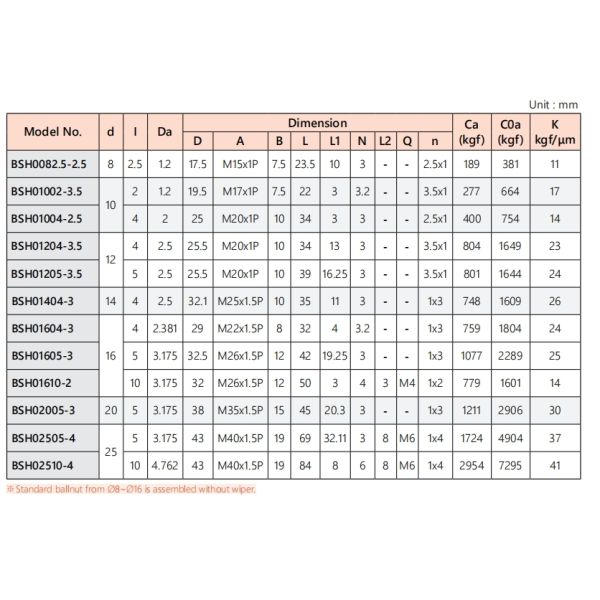

| Diameter: | 8mm |

| Lead(mm): | 2.5mm |

| Accuracy Grade: | C3,C5,C7 |

| Overall Length of shaft(mm): | Max 4000mm |

| Preload Grade: | P0 |

| Material: | Screw: S55C Nut: SCM415H Ball: SUJ2 |

| Threading Direction: | right |

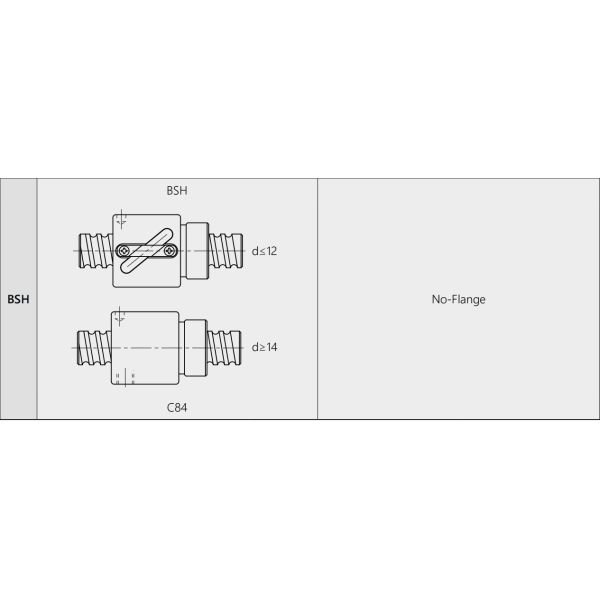

| Flange type: | double cutting |

| Proudct code: | F: rolled |

| Application: | delicate application in industrial application, machine tool and automation application |

| Installation: | Easy |

| Company Info. |

| NanJing TranzBrillix Linear Motion Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

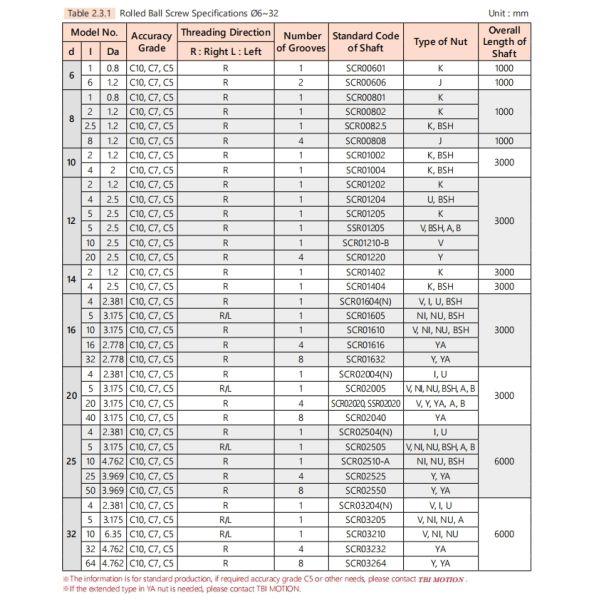

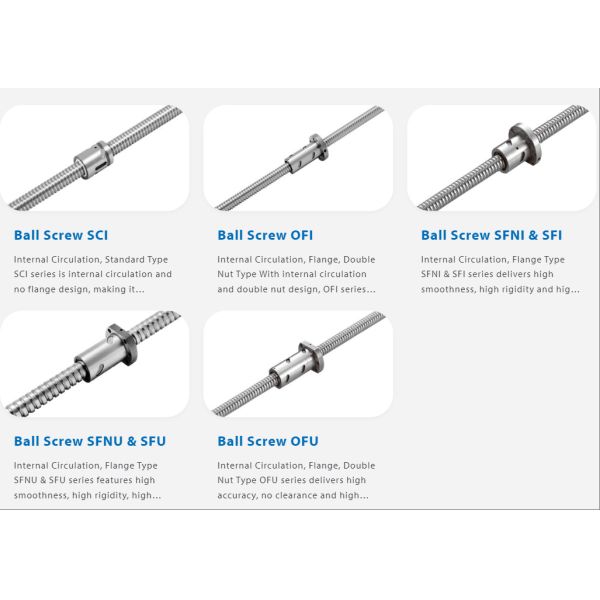

The TBI Ball Screw BSHR0082.5 represents a complete linear motion solution that combines precision engineering with ready-to-integrate convenience in a compact 8mm diameter package. This complete ball screw drive module showcases TBI's system-level approach to motion control, offering designers and engineers a pre-assembled unit that eliminates alignment challenges while delivering exceptional linear movement accuracy. The integrated design brings together TBI's renowned ball screw technology with high-quality support components, creating a cohesive system that performs seamlessly right out of the box. Particularly suited for space-constrained automation applications, medical devices, and precision instruments, the BSHR0082.5 delivers smooth, vibration-free operation thanks to its optimized ball recirculation system and precision-ground components. The module's thoughtful engineering ensures proper preload and minimal backlash while maintaining the flexibility to adapt to various mounting configurations. TBI's attention to detail shines through in the unit's balanced performance characteristics, offering both the responsiveness needed for dynamic positioning and the stability required for precise stops. The complete package reduces assembly time and eliminates guesswork, allowing engineers to focus on system performance rather than component integration. Whether incorporated into laboratory automation, optical positioning systems, or compact industrial equipment, this linear module exemplifies TBI's ability to deliver complete motion solutions that combine reliability, precision, and ease of implementation in a single, well-engineered package.

NJSKT is able to provide end machining of the ball screws according to your drawing. To help you see recommended end machinings for different types of housings. we will also machine custom ends to match a customer-supplied drawing. This image is of a drawing of the typical end machining dimensions that would be required for us to machine the ends. Other configurations are possible to machine as long as they are clearly drawn.

⑥Actual product photo

|