NanJing TranzBrillix Linear Motion Co., Ltd.

About Us

TranzBrillix is a specialized manufacturer and supplier of linear

motion components, including linear guideways, ball screws, and

linear bearings. With a dual-track strategy of independent R&D

and global brand partnerships, we deliver both cost-effective

proprietary solutions and premium international brands, meeting the

diverse needs of industries worldwide.

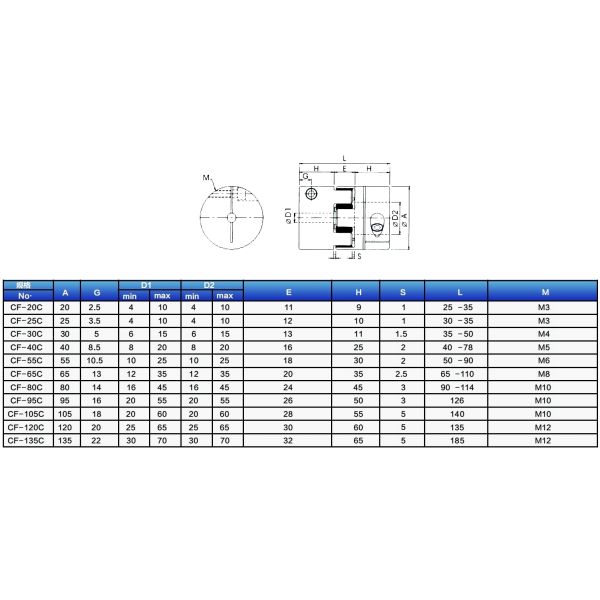

Linear Motion Products

Our guideways are fully compatible with HIWIN dimensions and

engineered for precision, rigidity, and long service life:

Global Brand Partnerships

In addition to our proprietary products, TranzBrillix is an

authorized distributor for globally recognized brands:

- TBI – Market leader in ball screw technology

- ABBA – Excellent cost-performance ratio

- REXROTH – Premium German engineering for high-end applications

This unique combination enables us to provide customers with both

competitive local manufacturing and trusted international brands.

Manufacturing Strength

- Advanced facilities — CNC machining centers, precision grinding machines, and

automated assembly lines

- High-volume capacity — scalable production with consistent quality

- Customization expertise — particularly in ball screw applications

- Short lead times — efficient scheduling and inventory management

- Quality assurance — comprehensive inspection processes and material traceability

Why Choose TranzBrillix Linearmotion

- Dual-track solutions: Proprietary products + world-class brands

- Comprehensive product range: From 5mm miniature guides to 65mm heavy-duty roller rails

- Premium materials: S55C, SNCM220, stainless steel, and carbon steel

- Engineering support: Product selection, design, and customization

- Reliable service: Global after-sales network and responsive support

With TranzBrillix you gain a one-stop partner for precision motion

solutions—covering everything from mainstream manufacturing to

advanced engineering projects.