| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Low Fin Tube |

|---|---|

| Brand Name: | Yuhong |

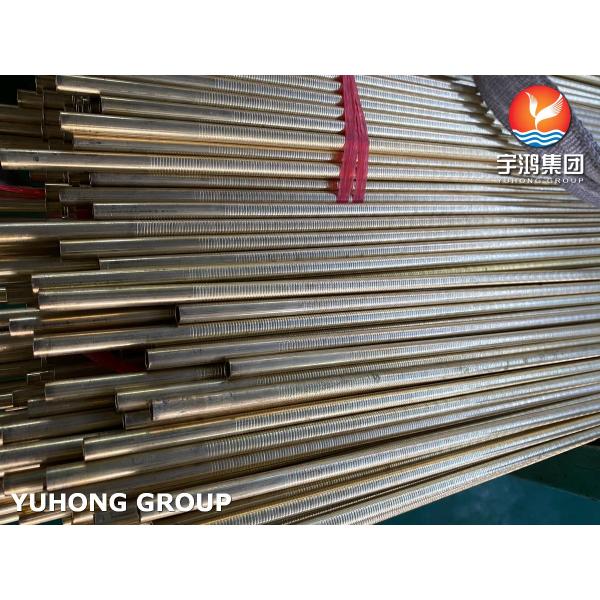

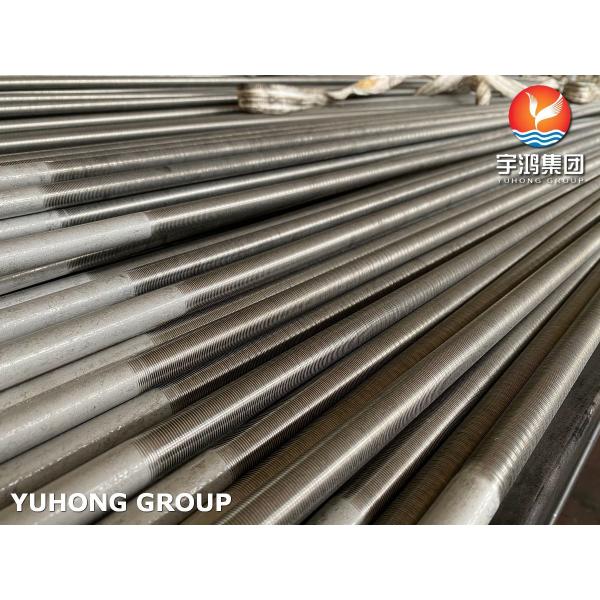

| Model Number: | ASTM B111 C71500 Low Finned Tube |

| Certification: | ABS, BV, DNV, CCS, LR |

| Place of Origin: | China |

| MOQ: | 2 PCS |

| Price: | Negotiable |

| Payment Terms: | TT, LC |

| Supply Ability: | According to Clients' requirements |

| Delivery Time: | 50-60 Days (Depend on Customer's Requirements) |

| Packaging Details: | Ply-wooden Cases with Steel Frames and Pipe's both ends with plastic caps |

| Product Name: | ASTM B111 C71500 (Cu-Ni 70/30) Low Finned Tube |

| Bare Tube Specification&Material: | ASTM B111 C71500 |

| Bare Tube OD: | 10~38mm |

| Bare Tube Length: | Customsized |

| Fin Height: | <1.6mm |

| Fin Thickness: | ~0.3mm |

| Fin Pitch: | 0.6~2mm |

| Application Industries: | Marine & Offshore Systems; Oil & Gas Industry; Power Generation; Chemical Processing... |

| Company Info. |

| YUHONG HOLDING GROUP CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

ASTM B111 C71500 (Cu-Ni 70/30) Low Finned Tube For Marin and Offshore Systems

ASTM B111 C71500 Low Finned Tube is a high-performance copper-nickel (Cu-Ni) alloy heat exchanger tube designed for enhanced corrosion resistance and heat transfer efficiency in demanding environments. Here’s a detailed breakdown:

1. Material ASTM B111 C71500:

(1) Chemical Composition (ASTM B111 C71500)

| Element | Composition (% Weight) | Key Role |

| Copper (Cu) | 65.0–70.0% | Base metal, provides ductility and thermal conductivity. |

| Nickel (Ni) | 29.0–33.0% | Enhances corrosion resistance and strength. |

| Iron (Fe) | 0.40–1.0% | Improves resistance to seawater erosion and impingement attack. |

| Manganese (Mn) | 0.50–1.5% | Deoxidizer, improves weldability and hot workability. |

| Zinc (Zn) | ≤ 1.0% | Trace element, minimal impact. |

| Lead (Pb) | ≤ 0.05% | Impurity control (avoid embrittlement). |

Notes:

C71500 = 70/30 Cu-Ni: Superior to 90/10 Cu-Ni (C70600) in corrosive environments.

Low impurities ensure stability in marine/chemical applications.

(2) Mechanical Properties (ASTM B111 C71500)

| Property | Value | Remarks |

| Tensile Strength (min) | 380 MPa (55,000 psi) | High strength for pressure applications. |

| Yield Strength (0.2% offset, min) | 125 MPa (18,000 psi) | Suitable for structural loads. |

| Elongation (min, in 50mm) | 30% | Excellent ductility for forming/expansion. |

| Hardness (Rockwell B) | ~65 HRB | Balanced machinability and wear resistance. |

| Thermal Conductivity | ~29 W/m·K | Lower than pure copper but stable under thermal cycling. |

| Electrical Conductivity | ~5% IACS | Not typically used for electrical applications. |

Additional Properties:

Corrosion Resistance: Exceptional in seawater, brackish water, and acidic/alkaline fluids.

Biofouling Resistance: Inhibits marine organism growth.

Temperature Range: -196°C to +260°C (cryogenic to moderate high-temp use).

Comparison with Common Alternatives

| Alloy | Composition | Tensile Strength | Corrosion Resistance | Typical Use |

| C71500 | 70Cu-30Ni | 380 MPa | ★★★★★ (Seawater) | Marine, LNG, Oil & Gas |

| C70600 | 90Cu-10Ni | 290 MPa | ★★★★☆ | Moderate salinity |

| C12200 | DHP Copper | 220 MPa | ★★★☆☆ (Freshwater) | HVAC, Power Plants |

2. Low Finned Tube Design

Fins: Integral, externally machined fins (typically 0.8–1.5 mm height) to increase surface area.

Purpose: Optimizes heat transfer in compact spaces while resisting fouling and corrosion.

3.The key features of ASTM B111 C71500 (Cu-Ni 70/30) Low Finned Tubes1. Superior Corrosion Resistance:

ASTM B111 C71500 (Cu-Ni 70/30) Low Finned Tubes are engineered for extreme environments where corrosion resistance, biofouling prevention, and thermal efficiency are critical. Their 70/30 copper-nickel composition and finned design make them ideal for:

1. Marine & Offshore Systems

2. Oil & Gas Industry

3. Power Generation

4. Chemical Processing

5. Industrial HVAC & Renewable Energy

|