| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Centerless Grinding Wheels |

|---|---|

| Brand Name: | Shine Abrasives |

| Model Number: | 1A1 |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1 pcs |

| Price: | FOB |

| Payment Terms: | L/C, D/A |

| Supply Ability: | 10 pcs in one week |

| Delivery Time: | 10 work days |

| Packaging Details: | one in one woodbox |

| Type: | 1A1, 6A1, 9A1 |

| Application: | cemented carbide bars |

| Dimension: | 200mm-700mm |

| Feature: | High Grinding Efficiency |

| Grit: | 50~30000 |

| Usage: | Carbide tungsten/ rod |

| Delivery time: | 7~10 days |

| Customized support:: | OEM, ODM |

| Company Info. |

| ZHENGZHOU SHINE ABRASIVES CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Rough, semi-finish and finish grinding of cemented carbide bars , PDC Cutter (Polycrystalline Diamond Compacts), tungsten carbide, ceramics, magnetic material, stainless steel bar, PCD and PCBN composites.

High roundness , good surface finish, superior grinding action, bulk removing of materials, competitive price, long life .

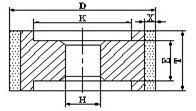

| Model | D (mm) | H (mm) | T (mm) | T (mm) |

1A1 1A1 | 200 | 75 | 50 | 5, 10 |

| 305 | 120 | 150 | 5, 10 | |

| 350 | 127 | 125 | 5, 10 | |

6A2 6A2 | 400 | 203 | 150 | 5, 10 |

| 455 | 228 | 205 | 5, 10 | |

| 500 | 127 | 205 | 5, 10 | |

9A1 9A1 | 600 | 305 | 125, 150, 200 | 5, 10 |

| 650 | 305 | 125, 150, 200 | 5, 10 | |

| 700 | 305 | 200, 400, 600 | 10 | |

| Other specification can be made according to customers requirements | ||||

Centerless Wheels For The Centerless Grinding Machines:

Centreless (centerless) grinding can perform excellent roundness of the work piece.The workpiece is supported by a work rest blade and set between a rubber regulating wheel that rotates the workpiece and a rotating grinding wheel.The mainly centerless grinding machines: Koyo, Crystec, Dedtru, Landis , Okuma, Paragon, Royal Master, Unison, WMV and so on.

Diamond centerless grinding wheel for tungsten carbide has the following features:

1. Long life span

2. Fine grit, standing sharp

3. Efficient batch external grinding

4. Good surface finish after fine grinding

5. Good precision keeping and wear-resistance

6. Used for rough grinding, semi-fine grinding and fine grinding

7. High roundness and cylindricity of workpiece and good

consistency of dimension

|