| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Stamping Bracket |

|---|---|

| Brand Name: | DX |

| Certification: | IATF16949 |

| Place of Origin: | China |

| MOQ: | 1000pcs |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 30000pcs per month |

| Delivery Time: | 25days |

| Packaging Details: | Bag,box/carton, pallet /crate |

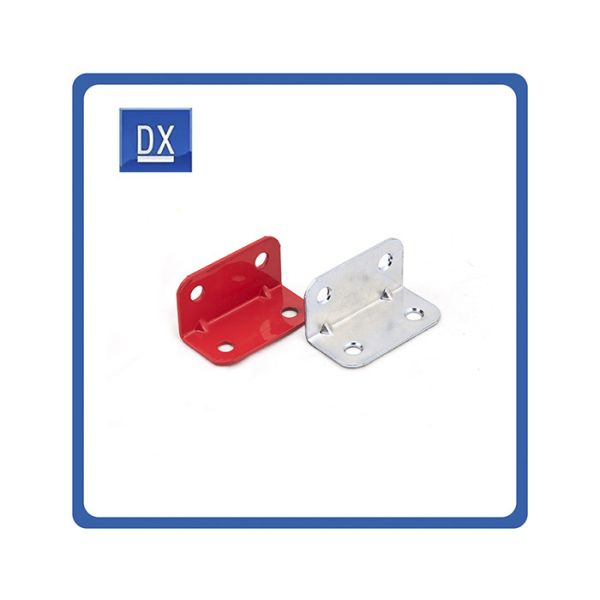

| Product: | Metal stamping powder coated bending bracket |

| Tolerance: | Laser cutting : +/-0.1 mm , Bending : +/-0.1 mm , CNC machining : +/-0.05 mm |

| Application: | Furniture, Industry, Automotive, etc |

| Surface: | Red powder coating,White powder costing, Black powder coating, White painting |

| Certificate: | SGS, ISO9001, IATF16949 |

| File formats: | Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| Service: | Customized OEM ODM |

| Other: | laser cutting plate , laser cutting tube ,bending ,welding ,stamping ,grinding ,drilling ,tapping ,cnc milling ,cnc turning etc |

| Company Info. |

| Jiaxing Dexun Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Metal stamping powder coated bending bracket

Stamping die is in the cold stamping process, the material (metal or non-metal) processing into parts (or semi-finished products) of a special process equipment, called cold stamping die (commonly known as cold stamping die). Stamping, is at room temperature, the use of mold installed on the press to apply pressure on the material, so that it produces separation or plastic deformation, so as to obtain the required parts of a pressure processing method.

| Description | Metal stamping powder coated bending bracket |

| Process | Cutting, Pressing,Bending, Shaping, Forming, etc |

| More | laser cutting plate , laser cutting tube ,welding ,grinding ,drilling ,tapping ,cnc milling ,cnc turning etc |

| Surface | Red painting, White powder coating, Black powder coating, White painting |

| Testing | CMM;Tool microscope;multi-joint arm;Automatic height gauge;Manual height gauge;Dial gauge |

| Tolerance | Laser cutting : +/-0.1 mm , Bending : +/-0.1 mm , CNC machining : +/-0.05 mm |

| Service type | OEM sheet metal fabrication services |

| Application | Furniture, Industry, Automotive, etc |

The notice:

1) Small heat conduction, thermal expansion (Austenitic system), so choose cooling but excellent performance of water-soluble lubricating oil.

2) Yield strength and high tensile strength, austenitic system of stainless steel work hardening, easy to produce rebound and transverse damage, so add plant equipment humidity, stiffness and wear resistance must be excellent, usually choose aluminum bronze (PVD, CVD surface treatment).

|