| Sign In | Join Free | My insurersguide.com |

|

| Sign In | Join Free | My insurersguide.com |

|

| Categories | Pre Engineering Building Forming Machine |

|---|---|

| Brand Name: | Saibo |

| Model Number: | Standing Seam Roof Roll Forming Machine |

| Certification: | CE/ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 300 sets per year |

| Delivery Time: | 70 working days after received deposit |

| Packaging Details: | Suitable for ocean shipment |

| Product Name: | Standing Seam Roof Roll Forming Machine |

| Main power: | 7.5KW |

| Steel thickness: | 0.5-0.8mm Prepainted Sheet; 0.7-1.2 Aluminium Sheet |

| Roll materisl: | Prepainted/Aluminium Sheet |

| Transmission: | Roller chains |

| Station: | 14 forming stations |

| Shaft diameter: | 75mm |

| Hydraulic motor: | 1.5kw |

| Shear blade material: | Cr12 |

RE65-600 Straight & Tapered Standing Seam Roof Roll Forming Machine with seaming machine

1. Equipment List

| Item | QTY |

| Rollformer (Straight forming &Tapered forming) | 1Set |

| Hydraulic System | 1Set |

| Hydraulic Cutoff Device | 1Set |

| PLC Control System | 1Set |

| 5T Manual Uncoiler | 1Set |

| Supporting Rack | 3pcs |

| Gantry Lifting Frame | 1Set |

| Automatic seamer | 1 set |

| Manual seamer | 2pcs |

| 20’GP container | 1 set |

2. Technical Parameters

| Main Parameters | |||

| Motor | 7.5KW | Thickness | 0.5-0.8mm Prepainted Sheet 0.7-1.2 Aluminium Sheet |

| Transmission | Roller Chains | Raw material | Prepainted/Aluminium Sheet |

| Stations | 14 Forming Stations | Coil Width | Max.680mm |

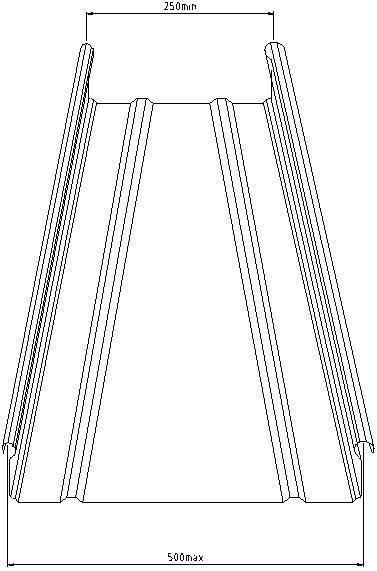

| Dimension | 5.7m×1.3m×1.0m(L×W×H) | Coverage Width | 300/400/500/600mm |

| Weight | 7.5T | Forming Speed | 0-15m/min |

| Shaft Diameter | 75mm | Min. Coil Width | 680mm |

| Hydraulic Motor | 1.5KW | Min. Coverage Width | 300mm |

| Shear Blade Material | Cr12 | Max. Coil Width | 680mm |

| Roller Material | 45# steel with harden treatment with hard chrome film | Max. Coverage Width | 600mm |

| Electrical Control System | PLC Frequency Control | Cut To Length | Encoder 10m±3mm |

| Voltage | 380V, 50HZ, 3PH | ||

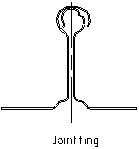

3. Profile drawing

Joint

Layout drawing:

|